Description

Accumulation conveyors are designed to momentarily hold and accumulate products before releasing them to the next production phase. With the use of an accumulation conveyor, it can help to control product flow when items from multiple lines must be merged into a single line and to even out product line variations. Accumulation conveyors come in two different configurations: accumulation table and alpine conveyor.

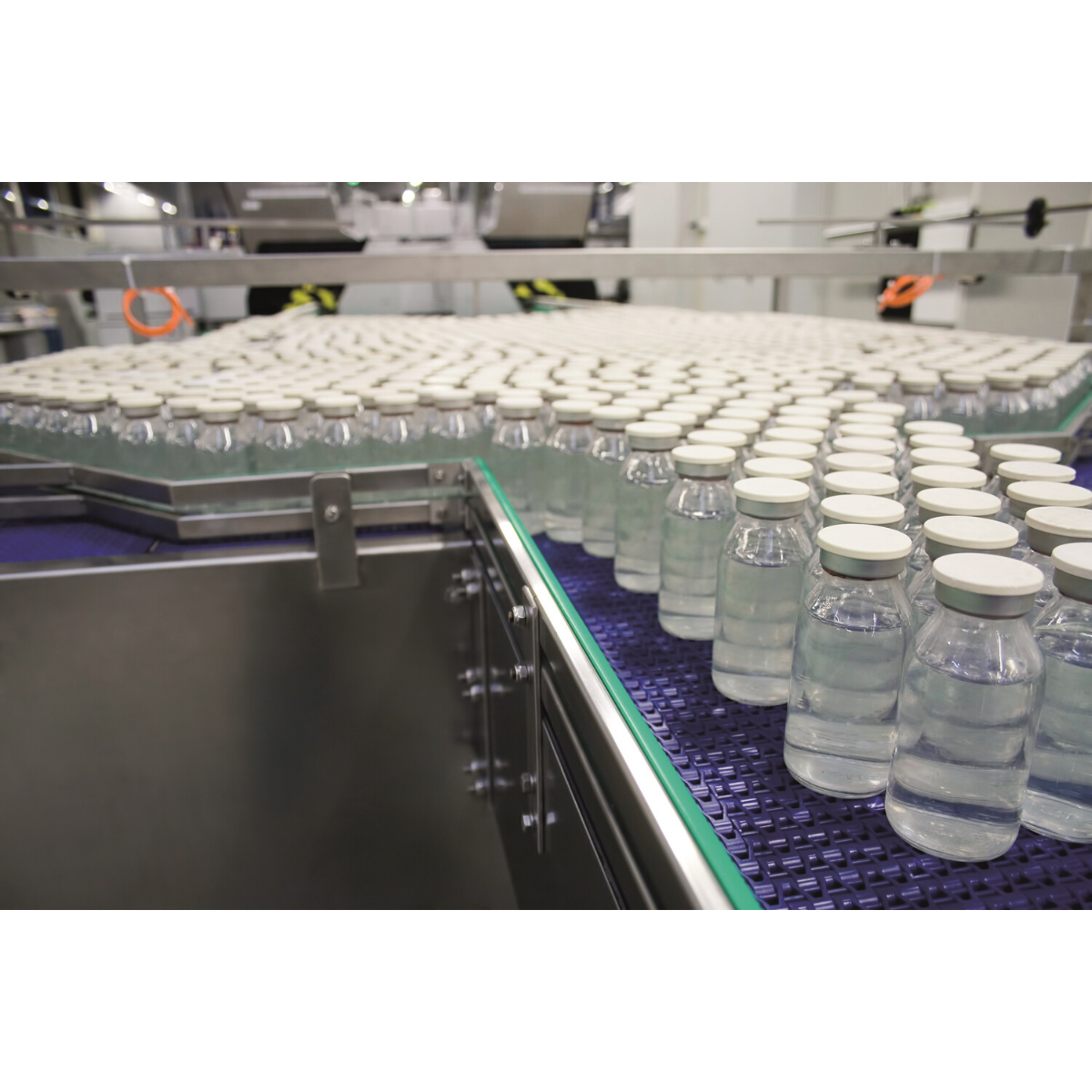

With a large storage capacity, the Accumulation table accumulates products to generate mass buffering in order to accommodate other processes in a production line. This equipment is driven by two gear motors which drive alternating conveyors in opposite directions. It also uses a straight running chain to avoid damage to the product. Falling products are discarded at the turning ends.

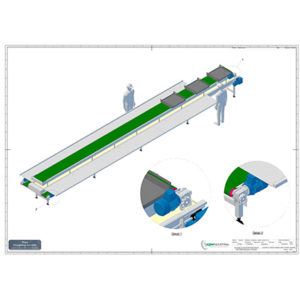

The alpine accumulating conveyor is compact with a spiral configuration and is used as an accumulation or elevating buffer zone between machines. It can also be used for cooling, drying purposes or to move the products vertically.

Key Features:

- Creates a buffer zone between processes.

- Merges multiple line items into a single line.

- Controls product line flow as well as singulates products on outfeed.

- Prevent congestion in conveying lines.