What to Look for During Scheduled Maintenance of Conveyor Systems

Unexpected equipment failure can interrupt your food production schedule. This can lead to costly downtime that can impact your bottom line considerably. Undoubtedly, regular maintenance prevents problems from arising. This is your opportunity to put any faults right and ensures that the equipment is working effectively. Without a doubt, regular equipment maintenance is key to preventing disastrous equipment failure.

Obviously, breakdowns do occur, especially when dealing with wet, sticky substances. However, there are some preventative steps you can take to ensure you are ahead of the game.

Preventative Measures

Where do you start when performing a regular maintenance check? We have put together a checklist for you. In addition, take a look at what to look for in each area.

- Inspect Gearboxes: In any maintenance check, we suggest inspecting gearboxes for oil leakage or signs of excessive heat or noise. Ensure you remove any build-up that might prevent the release of heat. Consider upgrading your geardrives to higher IP ratings to reduce the risk of failure in critical washdown locations.

- Assess all bearings and housings: Look for excessive greasing, burst or damaged seals. Also, look for signs of heat and noise. A golden rule with bearings – if there is any doubt replace it!

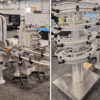

- Roller components: Inspect all rollers. Replace where necessary.

- Roller Endcaps and Bearings: Inspect all roller endcaps. Replace where necessary.

- Chains and sprockets – Inspect chain condition, stretch, side flexing. Often if the sprocket is worn this is a sure sign the chain is stretched. Replace if necessary. Also check alignment and tension. Tighten set screws. Clean and lubricate. Identifying whether chain is BS or ASA is very important.

- Pulleys and V-Belts: Inspect shafts and keyways. Make sure taperlock bushes are located correctly.

- Lineshaft drive and slave bands: These stretch over time and also can become hard if not run for an extended period. If the rollers slip to easily replace them.

- Lineshaft couplings and Universal joints: Check alignment and replace elements if necessary.

- Drive spools: Check and replace if necessary.

- Guards and covers: Make sure all guards are in place and with sufficient clearance to allow for chain or belt stretch.

- Frames and supports: Note any bent or damaged frames and supports.

By checking all of these areas you are sure to avoid any major casualties in your equipment. The wear and tear of moving parts, load, abrasion, and temperature can add up to unexpected interruptions. When that happens, EQM Industrial is here for you.

Easily find and order the correct parts for effective production line management.

Download our free Meat and Seafood Maintenance Guide today.