The Impact Of Critical Spares On Productivity

To maintain productivity, factories in any industry need spares of critical components. This is even more important for those involved in harvest-critical production.

The experts at EQM Industrial have been pushing this message for decades now, having seen too many examples of enforced down time and lost productivity due to delays in accessing replacement parts. They’ve also seen their fair share of stressed production managers when the delivery of those parts has been time-sensitive!

Gearboxes are a crucial component in almost every factory or plant, so take note of this near-miss!

Challenge:

Harvest, although short, is a pressurised time for many wine growers. Every vintage is unique, so can’t be replaced or wasted. Wine processing and filtering equipment is only used for a short time each season. But it’s critical that it is maintained and that spare parts are on hand to maintain production during the all-important harvest period.

Jarrod Hook from Hooked on Engineering in Blenheim provides engineering and maintenance support to many wineries in the Marlborough and other wine growing areas.

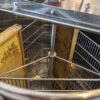

While preparing a Risk Assessment for a large winery, Jarrod identified STM gearboxes as crucial to the operation of the Rotatable Disk Vacuum (RDV) filters. These filters finely filtrate the wine, removing tiny particles and microbial organisms. The filtering process is time-critical to ensure the stability, clarity, and quality of the wine.

Action:

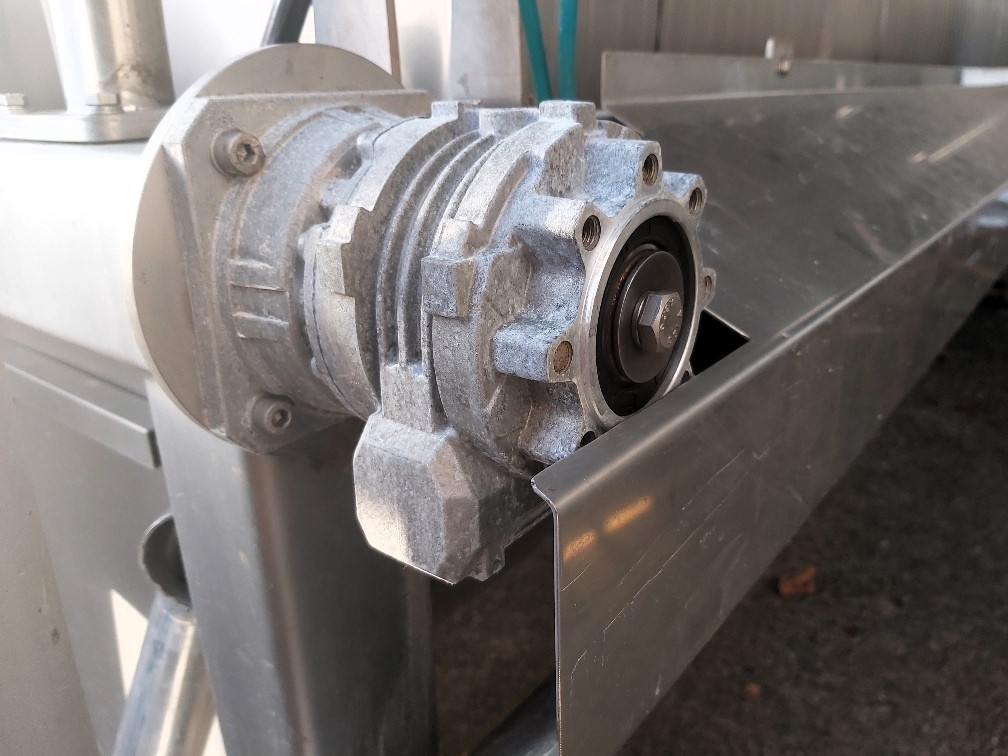

EQM conducted a site visit and identified that the filter drum and filter knife had special STM gearboxes, but there was very little information to identify them.

Drawing on his wealth of knowledge and expertise, Anthony was able to measure, then calculate what could be assembled out of Standard Line from STM to replace them.

STM has been designing and manufacturing gearboxes for over 40 years. In fact, they still make most of the designs they sold 30 years ago. So Anthony was able order exact replacements for Jarrod from the STM factory.

Benefits:

- No production downtime. A solid back up plan for any equipment failures during harvest sets the wine maker and production managers at ease.

- No compromised wine quality. Time-critical filtration keeps production on schedule.

- No lost vintage. A vital insurance policy!

Geardrive Features:

- Double reduction – two worm gearboxes joined together

- Torque limiter on output shaft

- 3 phase motor with external motorised fan to stop over-heating when a very slow speed is required

- All assembled out of the Standard Line from STM.

Avoiding Lost Production In Other Industries:

In case you need further convincing on the merits of keeping critical spares, these next examples relate to the chicken processing industry.

Two different chicken processors averted a substantial drop in production by being proactive about replacing crucial spare parts. In both cases, the vital components were Dertec geardrives which are manufactured in The Netherlands.

In one factory, the geardrive powered a thigh deboner that processes 6,000 thighs per hour. Imagine the loss of production if that was shut down while waiting on the order and delivery of a replacement from Europe!

EQM Industrial is the NZ agent for Dertec, so the team was able to save these clients precious time and many emails to The Netherlands by ordering the correct and genuine replacement part from Dertec directly. Within hours of receiving their clients’ requests, EQM had contacted Dertec for the new parts.

Minimising Down Time If You Haven’t Stored Critcal Spares

To ensure your vital production equipment stays operational , please call our experienced team for advice on building a reserve of critical spare parts.

Otherwise, EQM Rescue provides a rapid EQM response to limit downtime. Simply follow the instructions and we will call you back the same day with a speedy, but well-considered solution.

If the breakdown occurs out of hours, phone 0800 147 847 to be transferred to our EQM after-hours callout personnel.

Contact us for a solution to increase productivity on your production line today. Benefit from our knowledge, expertise and experience.

Better by Design.