Bottlenecks Stop Here. [Video] How bypass conveyors keep apple-packing on track.

Our customer called us in because a hiccup in the production line was causing a backlog. Cartons were getting stuck, waiting in line for the carton taping machine.

They knew that at EQM we have the knowledge, experience and ability to source and install the right machinery for the job.

About our client

Rockit Apples, well-known in New Zealand, are also world-famous.

Add high nutrition to these sweet and delicious miniatures, and you’ve got the ultimate snack food. And that’s the interesting part. The target market for this crunchy little treat is the snack food market, not the conventional apple market.

That’s why Rockit apples are prewashed and packed in clear, recyclable tubes. They can be bought and eaten on the run.

Definitely an innovator on the apple scene, Rockit Global is growing at a great rate.

No time for a time-out

The apples are stacked neatly into a tube, and then manually capped, labelled and packed into cartons. In this labour-intensive business, delays in production are costly. Thus something had to be done. So they came to EQM with the challenge.

What could we do to eliminate the delays on the carton taping line which occurred once, twice or more during a day?

Every time the carton taping machine had a minor issue, an operator had to make adjustments and reset the machine. As a result, the cartons in line for taping would build up dramatically.

A 2-step solution

- Firstly, our client invested in a second carton taping machine since the production is increasing dramatically over the next few years to justify this. This was set up parallel to the first carton taper. Thus up to 40% of the cartons could be redirected from packing line two.

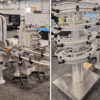

- Secondly, EQM collaborated with a local automation engineer. Consequently, we set up a band driven roller conveyor system that would easily re-route the cartons from one line to the other.

F-RATS, smart motors and multiple settings

Central to the junctions of the conveyor lines and the bypass conveyor is what is called an F‑RAT. (Flat Right Angle Transfer).

These F-RATs are controlled by three pre-programmable smart cards driving motorised rollers designed to transfer cartons at high speed left or right. We installed them in the existing Tranzband roller conveyor frame.

To connect the two lines a short roller conveyor bridges the gap creating a bypass. Two reversible smart motors with control cards that can be activated directly from carton sensors to drive it.

We engineered a plan that means that if there’s a minor glitch on one line, a switch is flipped and Plan B swings into action:

Plan B

- When a carton follows its normal course on the line, it moves onto the F-RAT where it continues in the same direction driven by small wheels.

- If the carton is to be diverted it is stopped (for about a second).

- Rollers, built at 90° to the mainline, lift. The carton switches direction and proceeds to the alternate carton taping machine.

- While this is happening operator repairs or resets the carton taping machine.

This not only takes the pressure off the carton taper operator but stops the cartons from both lines accumulating and keeps the production lines running smoothly.

The operator is then free to do a careful and thorough repair of the carton taping machine. - As soon as a glitch is rectified the production line can now flip back to its normal flow pattern without having to clear a build-up of cartons.

Going forward

We expect the future growth of this enterprise to be enormous.

Rockit apples are becoming more and more popular and future plans include planting a further 800 hectares of these trees over the next 5 years.

The Packhouse Production Supervisor is very pleased with our accomplishment.

We and our collaborators are glad to have had this opportunity to partner with Rockit to streamline their production.

Having made the system relocatable we look forward to continuing to add to their carton handling automation as they relocate to a new Packhouse in 2021.

Want us to eliminate your bottlenecks or create bypasses with smart conveyor automation, we will be pleased to hear from you so contact us today!