Custom rotary table packs a bonus for fresh vegetable producer

Vegetables. Fresh from the field. Green and crisp, they’re prepared, washed and sorted while at the peak of freshness. Soon they’ll be packed. Some for sale close to home in New Zealand, and others heading out onto the international market.

Production has revved up with the addition of a second packline with a new extra-large rotary table.

See how this came about.

The Project: Large stainless-steel rotary table

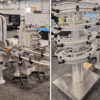

A 2450mm diameter round table, designed to accumulate leeks and other produce at the end of an automated vegetable washing conveyor line.

About our client

This family-run, commercial vegetable growing operation is based in the Horowhenua region of New Zealand. The company is renowned for freshness, taste and uncompromising quality in what they promise to their customers.

A simple commitment, but when you’re talking about a perishable product, that can be a challenge to follow through.

They’ve followed a policy of continuous technical improvement, and kept up with advances in agriculture. Could this be the secret of their success?

Some history

Back in 2018 our customer tasked us with supplying a large stainless-steel rotary table to replace an existing fibreglass one which was a bit worn out.

It had to be extra-large so that it could accommodate a lot of packing staff when operating at full production. At 2450 mm across, that was the biggest rotary table we’d made to date. Much bigger than our standard rotary tables.

In true forward-thinking mode, our customer came up with some unique design modifications, such as small drainage holes towards the center of the table to assist with the daily washdown. It also has a raised centre piece which keeps the produce nearer the edges of the table within easy reach of the workers.

The challenge

The food industry is an essential service. COVID or no COVID, we need our greens. In fact, their orders during lockdown were phenomenal, and they had to increase production.

Increasing production means increasing workers. When you’re keeping people distanced for safety this is a challenge.

Our customer sees their staff as their greatest asset. As such, they are determined to keep them safe and healthy.

How could they keep up with the booming orders and keep their workers distanced and safe?

The answer was obvious

Another oversized accumulating table was ordered.

We based our design on the 2018 model, but, as usual, we listened to our customer, got his feedback and worked it into the new design. We changed the drive wheel orientation and geardrive location to improve the reliability and deliver a more consistent rotation regardless of how much product was on the table.

Automated washing conveyor line

At the height of Lockdown we organised a special modular belt for this second washing and packing line which now feeds the new rotary table. The increased demand for quality vegetables, since everyone was at home, created a need for the second line to be set up very quickly. This was achieved within 2 weeks.

The result

A top-of-the-line, custom designed and built stainless-steel rotary table. Made with quality components, and ready to deal with any kind of produce that lands in it.

And the bonus?

One great outcome of the new table and second line was improvement to worker safety. Add the bonus of production increasing and we have a happy client with a great result.

Interested in improving your productivity?