NZ chicken meat packer eliminates flaking epoxy with aluminium washdown gearboxes

A chicken processing line that starts with live birds that finally emerge as neatly packaged product needs the best of the best to keep everything running smoothly and hygienically. That’s why our long-time customer decided to upgrade the gearboxes and motors on their conveyor system.

And called on EQM to help.

A progressive family business

Established more than 60 years ago, this company holds true to its values of hard work, commitment and respect.

Pioneers in the New Zealand food industry, their dedication to continuous improvement led them to upgrade the motors and gearboxes for their conveyor systems.

The assignment

Live chooks are conveyed on plastic trays into the slaughterhouse.

The birds are then plucked, eviscerated, chilled and processed.

Another conveyor beneath the main conveyor takes feathers and other waste products directly out to the waste bin.

For a long time epoxy-painted gear drives were used, but there is a reason why you don’t want them in the food-processing industry. They chip. And flake. You really don’t want to risk those bits turning up in your chicken.

Of course, as an accountable food packer our client has always taken measures to make sure this doesn’t happen. But who wants to take the risk or be stuck with that extra maintenance?

Our solution – we chose Z series hygiene aluminium from Cleangeartech

These particular conveyor systems move raw products for further processing.

They also take waste products away from the processing lines.

Both of these applications allow for milder cleaning solutions than can be used in most food processing operations, so we were able to use aluminium. (Aluminium reacts with harsh chemicals.)

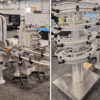

We replaced the drives of four conveyors with our Clean-Geartech Z series aluminium gearboxes and motors.

Great for use in washdown areas, these motors and gearboxes are ultra hygienic.

- The aluminium surface is NTT™ treated. No possibility of flaking paint because there is no paint

- The motor is totally enclosed IP69k– easy to wash down after each cycle.

- Rust-free, so great for damp environments.

And the final result?

The engineer informs us that the whole upgrade is going very well.

No problems with these treated aluminium geardrives at all!

When harsh chemicals are needed

Our go-to is the Cleangeartech range of full stainless-steel motors and geardrives. These gear drives can withstand harsh cleaners and chemicals with a pH of more than 10.

Suitable for all types of food processing because:

- Hygiene issues are eliminated

- There’s less maintenance downtime

- Reliable performance you can count on

- Perfect for harsh environments

- And long lasting.

We installed some of this range for a customer more than 8 years ago

and they haven’t touched them since!

Contact us if you’d also like to do us out of repeat business!