Preventative maintenance gives you peace of mind

At EQM there’s not a day that goes by when we don’t get a phone call from a stressed-out production manager looking for some replacement equipment following a breakdown.

We pride ourselves on putting the caller at ease as quickly as possible. Getting an understanding of the issue, the type of equipment needed and whether we can supply a temporary or full replacement as quickly as possible is how we achieve this.

In the food sector, it’s also important to be on top of hygiene and safety.

Food manufacturing facilities are churning out processed and pre-packaged foods using various pieces of equipment. This means it is extremely critical to ensure that the production is completely safe, hygienic, and efficient to protect the health and safety of the consumers. Having well-maintained equipment in a facility achieves this.

The safety and hygiene standards of the food being processed will be high when equipment is well-maintained. Conversely, ill-maintained equipment will break down more often during manufacturing and processing. Thus, the integrity of the production processes and the food being produced is compromised. The last thing you want is downtime, especially unplanned downtime.

EQM has come up with some helpful preventive maintenance practices tips:

Equipment inventory

First of all, take inventory of all the equipment used for food production. Check what you have, how much you have and what you need. It is important to note that different types of equipment pose different hazards and risks. Your personnel must have a clear understanding of how to maintain each of them properly.

Have a maintenance schedule based on operations

Follow the manufacturer’s guide on how to maintain different equipment. These guides are generally broken down into daily, monthly, and annual maintenance categories. Go through them carefully and create a master schedule. This will allow you to track and keep to important maintenance dates. You must also consider how maintenance will fit into your operational schedule. Would shutting down the production one day prior to maintenance be a good idea?

Document every procedure

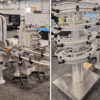

Keep a record or document which is always in one location and is accessible to all staff. Every document must contain detailed descriptions of how each machine must be maintained and serviced. This will come in handy when someone new takes over the job or a query is raised regarding the procedures. Take photos of equipment and their specification plates too. Keep this in the document and it will make it easier for us to supply a replacement.

Accountability

Make someone accountable and in control of conducting all the maintenance programs. If you do not assign authority to someone, the staff may be tempted to skip certain maintenance procedures. Ensure that you make someone accountable who is responsible, has knowledge of food safety, and is dedicated to the same.

Supplies and parts

You need normal hand tools to service and maintain certain equipment. You may even want to include spare parts, various types of lubricants and critical back-up replacements. We recommend having some supplies in stock, especially if they are hard to find. It is advisable that you prioritize the supplies based on the most critical and hardest-to-find to the least critical ones.

Traceability

Finally, maintain detailed records of equipment maintenance. Whenever your facility is inspected or audited for safety standards these records provide evidence. Maintenance records also ensure traceability, which is critical in the food industry.

Forget the saying “If it ain’t broke, don’t fix it”. When it comes to food safety and efficiency, rather aim to fix it before any equipment has a chance to break.

EQM can offer quick response, equipment inventory archiving, installation support and even service maintenance reminders.

We are the ones that will ensure your equipment is optimised to the best performance possible. Get in touch with us today.