Unitec rep visits NZ

The world’s leading innovator in fruit defect sorting and packing line equipment, Unitec Group, visited New Zealand for the first time in December.

Unitec’s recently appointed Oceania Region representative; Benedetta Ricci Iamino, was given a tour of New Zealand’s premium growing regions – Hawke’s Bay, Bay of Plenty, Marlborough and Central Otago by Anthony and Tim Bloxham. Benedetta has extensive experience and knowledge in Cherry and Blueberry defect sorting systems having sold many lines. Her knowledge on other fruit products also impressed those we visited.

Anthony said the trip started with a visit to Bay of Plenty to see kiwifruit packhouse operations with the aim of assessing how the industry operates and what their current and future requirements for internal and external defect sorting is likely to be.

“We also presented Kiwi Vision Technology, which Unitec has developed and has operating very successfully in Italy”.

Unitec has setup a number of kiwifruit turnkey sorting and packing lines with one Bin tipping to pallet stacking line in Italy called Gullino packing for Zespri. Therefore, they are familiar with Zespri standards and requirements which appealed to many NZ kiwifruit packers. Benedetta also collated data on common New Zealand fruit defects so that this could be recorded for potential use in equipment supplied to New Zealand in the future.

In Hawke’s Bay, EQM introduced Benedetta to a cross section of the fruit industry starting with special apple varieties, cherry and blueberry packing and stonefruit systems. There is a lot of interest in the latest in apple defect sorting equipment offered under the Unisorting brand currently being developed in Italy.

Unitec is world renowned for its Cherry Vision defect sorting equipment within the cherry sector and how this automation enables the reallocation of the majority of the labour currently employed to do hand sorting, to other parts of the facility.

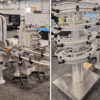

A week was spent down in Central Otago visiting Cherry and stonefruit packhouses, culminating in the launch of Unitec’s first 8-lane Cherry Vision turnkey sorting and packing line.

“This first turnkey line was delivered in 8 containers, assembled and operating onsite in less than three weeks. Just in time for an early start to the 2017 season and a really successful start to Unitec’s first installation in NZ.”

This was Benedetta’s first visit to New Zealand before she moves to Melbourne, where Unitiec will base its first sales and technical support office in the Oceania region servicing Australia, New Zealand and China/Asian markets.

“Benedetta was impressed by the quality of New Zealand’s fruit as well as the desire of the industry to be at the forefront of technology, and she put this down to the fact that exporters wanted to ensure that due to the tyranny of distance from market, their products would arrive in the best condition and graded to the highest standards.”