Why a leading Fruit Packer made it a Triple

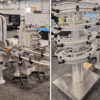

It was getting a bit old for them. The fruit brush washer units were needing their bearings replaced every season…

Read more

Superior crops, superior handling

This export-focused company has processes in place to ensure that their fruit is packed, stored, transported and marketed to meet the exacting standards of the world stage.

As an organic packhouse they are rigorous about specific needs, timelines and quality standards. A streamlined system is a must.

A Wet and Dirty Environment

Fruit cleaning creates dirty water. This water was penetrating the seals in the bearings, causing the bearings to fail by wearing out or seizing up.

They tried a range of protection shields to stop the water getting into the bearings, but had found nothing to resolve the problem.

Constant bearing failure just wasn’t an option.

Triple Sealed Bearings to the Rescue

EQM suggested using the Challenge Triple Seal Bearings. These bearing units can operate in almost any environment. They are very competitive as a direct replacement spherical bearing complete with seals. This greatly decreases the cost of bearing units.

Sure enough. To quote the packhouse manager, “The triple seal bearings are definitely worth changing to and are very effective in wet areas. We have only replaced 18 bearings this time rather than 240.”

And “Standard bearings wouldn’t even last one season. We have been amazed at how long they’ve lasted — they’re now into their third season. They’ve saved time by almost eliminating bearing failure on the brush washers and saving on maintenance time.”

Technical Features (or why they work)

Triple-sealed bearings are held on the driven shaft with Challenge’s unique balled setscrew which features an embedded ball in its tip. Compared to cup-point setscrews or knurled cup-point setscrews, the balled setscrew provides much greater resistance to loosening as it does not readily loosen due to vibration or impact.

Challenge bearings conform to the JIS (Japanese Industrial Standard) for UC-type bearings. They’re able to be used as a lubricatable bearing, but are also interchangeable with the conventional bearing units of other manufacturers.

This makes them a ready replacement for existing bearing units whether they are metric or imperial.

One Step Further

“They are so satisfied that they are now introducing triple seal bearings throughout the plant, even in dry and dusty environments.” says Anthony of EQM. Triple-sealed bearings feature a secure bearing seal with three lips. This special seal offers reliable dust proofing and water proofing superior to those of standard bearings.

A bearing life longer than that of a standard bearing unit =

- Extended maintenance intervals

- Cost cuts for maintenance, lubrication and replacements

- Less down time for your packing line

- Great ROI for You

Click Here to Make it A Triple Today!