Why is maintaining your equipment so important?

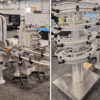

Equipment Maintenance

Here at EQM Industrial we understand the importance of a properly implemented maintenance schedule. And with the impending maintenance shutdowns of the seafood and meat packing factories looming, we wanted to take this opportunity to highlight the steps you can look at taking in your business to ensure you are ready.

Why focus on maintenance? Because it is an important factor in quality assurance and in some cases determines the long-term success of a company. Poorly maintained resources can cause instability and partially or completely pause production. Malfunctioning machines or complete breakdowns can become a costly process for most companies.

Establishing the importance of routine servicing firmly in the minds of your employees and workers is the first step in ensuring a regular, scheduled, and effective maintenance program.

Steps you can take to Avoid Big Problems

- Keep Your Conveyor Belt Clean

Belt maintenance begins with belt cleanliness. Even the smallest of residues of oils, greases, or particulates in the nooks and crannies of a conveyor belt system can wear down a conveyor belt. Leading to throwing a belt out of alignment, causing slippage, or corroding materials. A thorough and regular cleaning and/or sterilization protocol can save you time and money down the track.

- Change Fluids and Oils

Changing fluids on time extends the healthy life of a machine. In much the same way as a car operates, conveyor belts incorporate a system of closed gearboxes, and regularly changing their oil will ensure a long and trouble-free lifespan.

- Check Your Conveyor Belt Tracking

Careful conveyor belt adjustment can also prevent uneven wear-and-tear and belt slippage. Just like the tires on your car, improperly aligned conveyor belts will “pull” in one direction, stressing and wearing it down unevenly, causing it to catch or slip over time.

How do you know you have tracking problems? Listen out for vibrations or grinding noises, as well as looking for spots of uneven wear or damage, or frequent slips and stoppages.

- Watch Out for Signs of Conveyor Belt Slippage

Conveyor belt slippage is by far the most common maintenance problem and it can cause a whole series of additional problems, such as work stoppage, material loss and damage, and even employee injury. You need to stop the slide before it starts.

- Make Sure the Frame is Square and Level

It is hard for your conveyor to run properly if the entire system is tilted at an unusual angle or thrown out of alignment. This can occur from the regular motion of the machine as well any number of other factors. You can easily confirm the state of your frames by using a standard level and checking to make sure that both sides are even.

- Replace Any Worn Parts

This advice should go without saying, but it is so important that it is worth drawing special attention to. If any single part of your conveyor system begins to wear down, it needs to be replaced. If it continues breaking down without replacement, it will put added strain on the other parts as they work to carry the extra load that the damaged part is unable to. This situation results in the rest of your system breaking down more quickly or malfunctioning and needing to be shut down altogether.

Additional Tips for Conveyor Maintenance

If you actively check your conveyor belt’s activity and prepare to handle problems, your operation will run smoothly. We suggest the following tips when caring for your conveyor belt:

- Prepare for Emergency Repairs – This is valuable for belts that you actively use throughout the day. Have a plan for emergency repairs by stocking equipment such as cold-curing supplies or metal fasteners so you can repair rips quickly. It is also wise to have a plan of action for production. Will you stop that line completely, or can you move it elsewhere while you make repairs?

- Stock Spare Parts – Things such as sprockets, motors and belts will need to be replaced over time. To see what we can supply for you, check out our video of Clean Geartech gearboxes and motors.

- Track Your Belt’s Lifespan – How long do your conveyor belts typically last in your factory? If you know how long a belt lasts, you can make sure you are actively caring for it to support that lifespan.

- Use Preventive Maintenance – The best way to avoid a severe malfunctioning error is to practice a proactive maintenance schedule. Keeping a regular check on your machinery and the working parts will ensure you find a problem before it becomes a large issue ultimately making your line more productive.

- Keep Documentation – Make a note of any repairs you perform and write down the state of your parts regularly in a logbook. If a more significant problem arises, you will have these notes to see repairs you have made in the past, and if the state of your equipment over time.

So, are you ready for the shutdown period? Will your team be able to carry out the maintenance schedule you have in place?

To order your spare parts and ensure a smooth maintenance period, contact our team today.